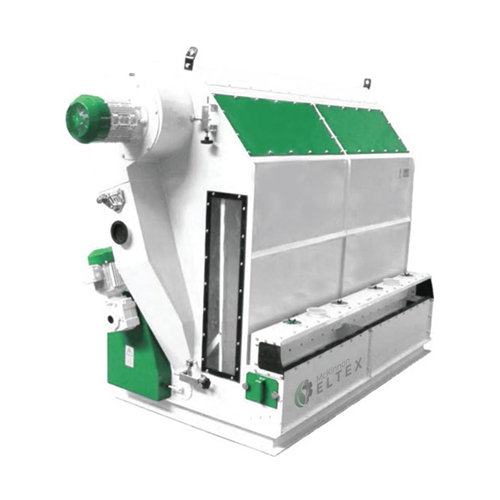

About Recycling Aspirator

FEATURES

- Energy-Saving Equipment

- Small built-up space

- Low cost of installation

- Savings of filtration area

- Limited vacuum in the working hall

- Low cost of service

| Type |

Max Output [t.h-1] (1) |

Power Input [kW] (2),(3) |

Aspirator Air Volume [m3/min-1] |

Net Weight [kg] |

Built up space [m3] |

| Asana 10 |

10 |

2.2 + 0.55 |

6 |

2.7 |

15 |

| Asana 15 |

4 |

4.0 + 0.55 |

339 |

3.7 |

15 |

| Asana 15M |

6 |

4.0 + 0.55 |

428 |

3.7 |

|

- Capacity Depends on the grain sort, moisture, grade of contamination

- Drive of the fan: Flanged electric motor

- Drive of the worm, air lock and feeder: Geared electric motor Power supply 415V, 50Hz

Models of Recycling aspirator

- ASANA 10:Self standing machine with 600mm wide, built-in feeder with socket 100mm suitable for scouring machine / separate free standing machine

- ASANA 15:Self standing machine 995mm wide, built-in feeder suitable for scouring machine /separate free standing machine

- ASANA 15M:Used with the screen grader Ariel 60 / separator , 995 mm wide, inlet adaptable to the screen grader outlet, plate magnet separator instead of the feeder

Superior Sorting PerformanceThe recycling aspirator utilizes advanced sorting technology, achieving high efficiency in material separation. Its automated operation reduces manual labor and enhances productivity, making it ideal for modern recycling facilities. The machines precision ensures contaminants are minimized, maximizing the value of recycled materials.

Built for EnduranceConstructed from premium stainless steel, this aspirator offers exceptional resistance to wear and corrosion, guaranteeing long-term reliability. The one-year warranty demonstrates our commitment to quality and customer satisfaction, while its standard size makes integration into existing systems straightforward.

FAQs of Recycling Aspirator:

Q: How does the Recycling Aspirator improve sorting efficiency?

A: The Recycling Aspirator uses advanced automation and precision engineering to effectively separate recyclable materials based on size, weight, and type. This results in a higher purity rate, minimizing contamination and increasing the overall quality of recycled products.

Q: What materials is the aspirator made of and why is it beneficial?

A: This equipment is manufactured from high-grade stainless steel, providing strength and resistance against corrosion. The material ensures long-lasting performance, minimal maintenance, and a hygienic processing environment.

Q: When should I perform maintenance on the Recycling Aspirator?

A: Routine maintenance should be conducted according to the usage intensitygenerally, a standard monthly inspection is sufficient for most operations. Regular cleaning and checks help maintain optimal efficiency and extend the machines lifespan.

Q: Where can this aspirator be used effectively?

A: This machine is suitable for recycling plants, waste management facilities, and industrial environments focusing on material recovery. Its standard size and automatic operation make it easy to install and integrate into various production lines.

Q: What is the process for using the Recycling Aspirator?

A: Simply load mixed recyclable materials into the machines inlet. The aspirator automatically separates them using airflow and sorting mechanisms, directing sorted materials to specific output bins with minimal human intervention.

Q: What are the main benefits of using this high-efficiency aspirator?

A: The aspirator boosts operational efficiency, reduces labor costs, and delivers consistently high-purity sorted materials. Its robust construction guarantees longevity, while the stainless steel build ensures hygiene and easy cleaning.

Q: How does the warranty support work for this product?

A: We offer a one-year warranty covering manufacturing defects and core components. During this period, our team provides prompt service and support, ensuring minimal downtime and continued productivity for your operations.